Objective

Create a drone that can drop a red or blue ball based off which color it detects in front of it. It also must only drop if it is a certain distance away.

Execution

We used an Arduino, “PixyCamera”, and ultrasonic sensor to accomplish this task. The whole drone was either laser cut or 3D-printed, so the only tool required for assembly was a screwdriver. The landing gear featured an “active” design, meaning it was able to absorb impact with springs that were placed inside each landing gear.

Personal Role

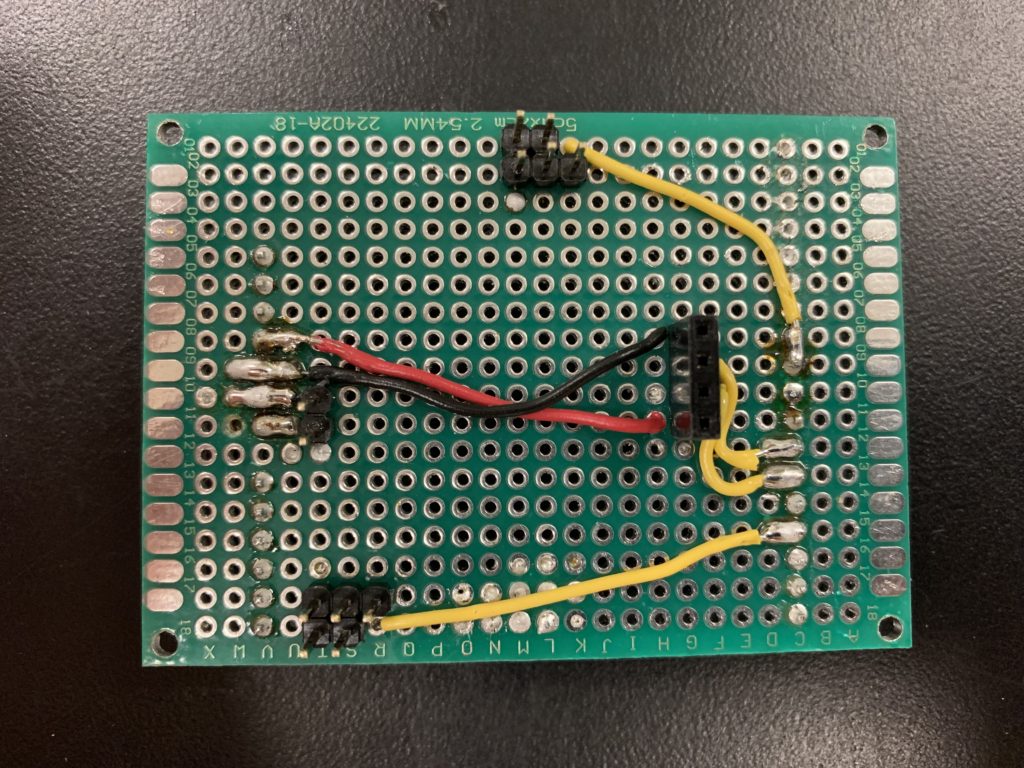

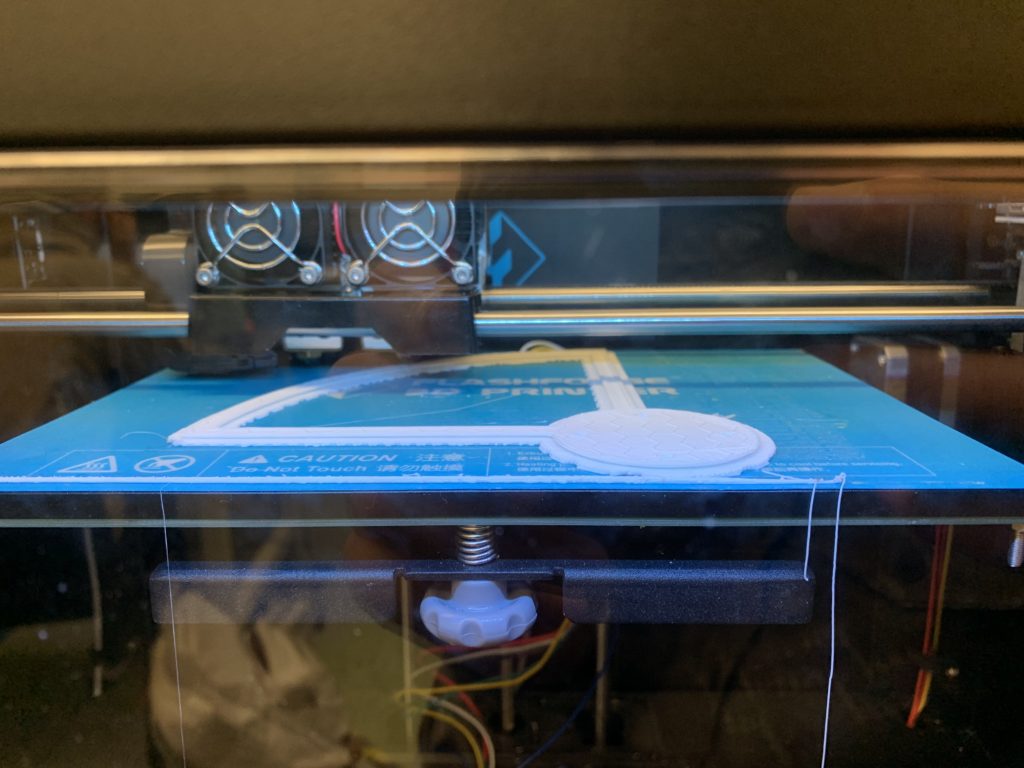

I was the team lead for a team of six that was involved in this drone. I designed the main chassis and designed/fabricated the circuit. I was also responsible for communicating with the rest of the design team, making sure parts were compatible with each other. This meant I put together the SolidWorks assembly (pictured below) to ensure compatibility before fabrication. Several revisions were made on each part. Rapid prototyping was streamlined with 3D printing and laser cutting.

Custom modular circuit

3D-printed ball drop mechanism

Propeller guard fabrication

Chassis fabrication on laser cutter

Structural assembly