Why do you need a jig?

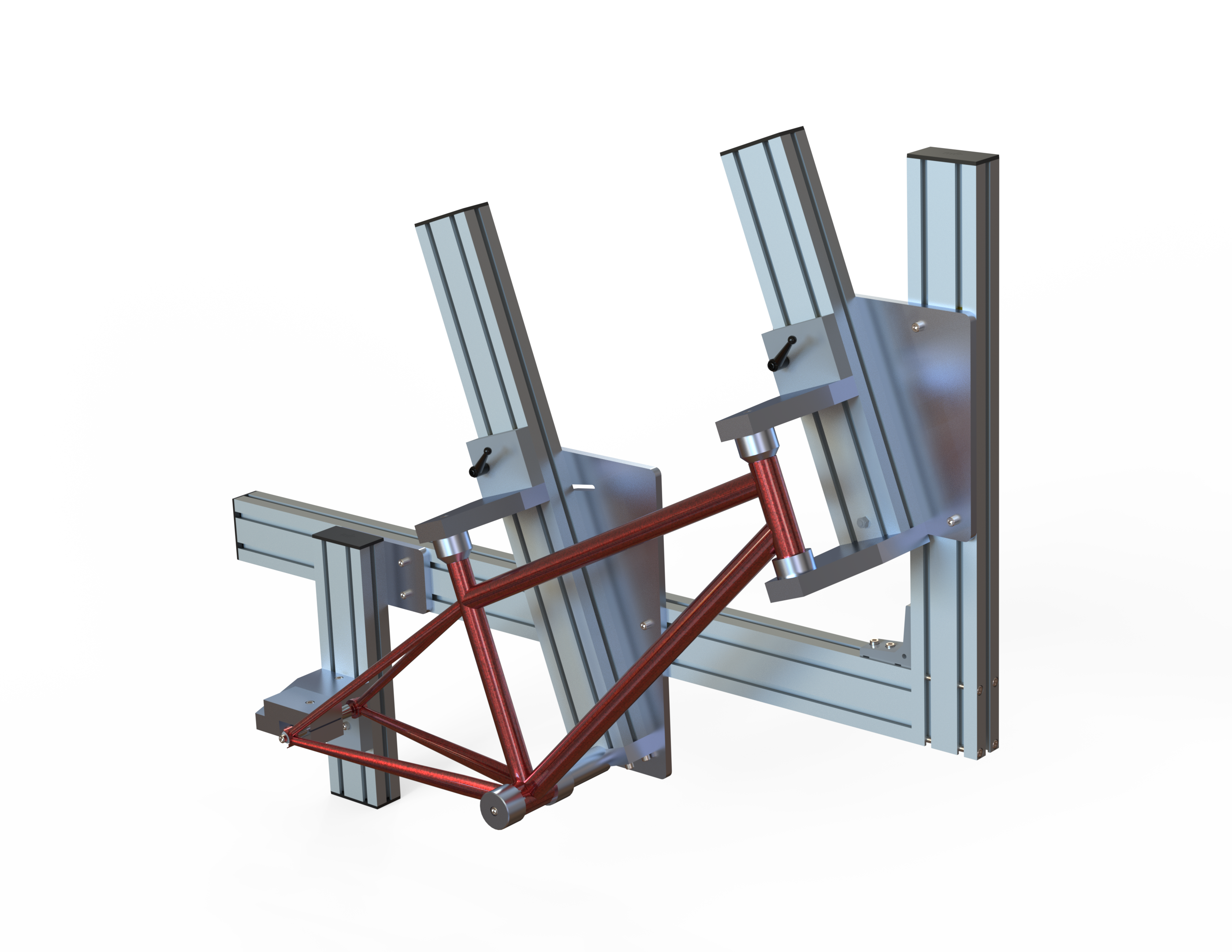

In the bike world, geometry is king. It decides if your bike is suited for pedaling up a road or flying down a rocky decent. Even the slightest change in head tube angle (a degree) can change the whole feel of a bike. Designers use specific industry accepted dimensions to tailor bikes for certain applications.

When it comes time to fabricate, it is crucial that all tubes lie in the exact positions decided during design. Without a rigid jig, it would be impossible to TIG weld everything accurately.

Design verification with Excel

I wanted verification that the jig would work for any type of bike we would want to make. To make this happen I created a design table in excel that controlled the bike geometry in the model. I could input as many bike geometries as I wanted from manufacturer websites and see how the jig would change to fit these different bikes. I tested everything from BMX bikes to downhill bikes to road bikes.

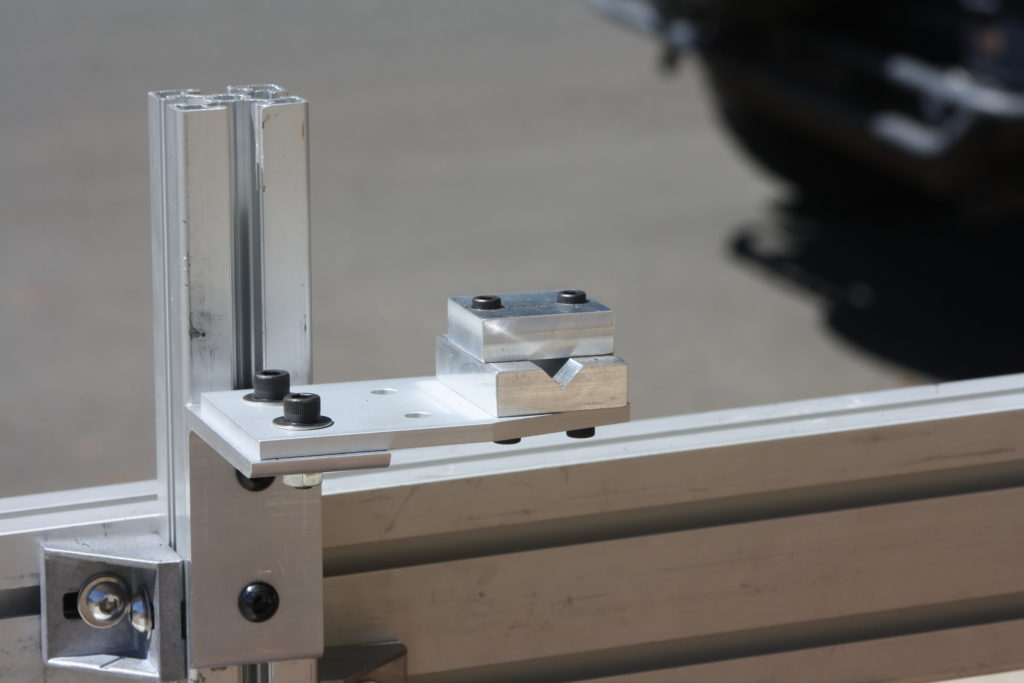

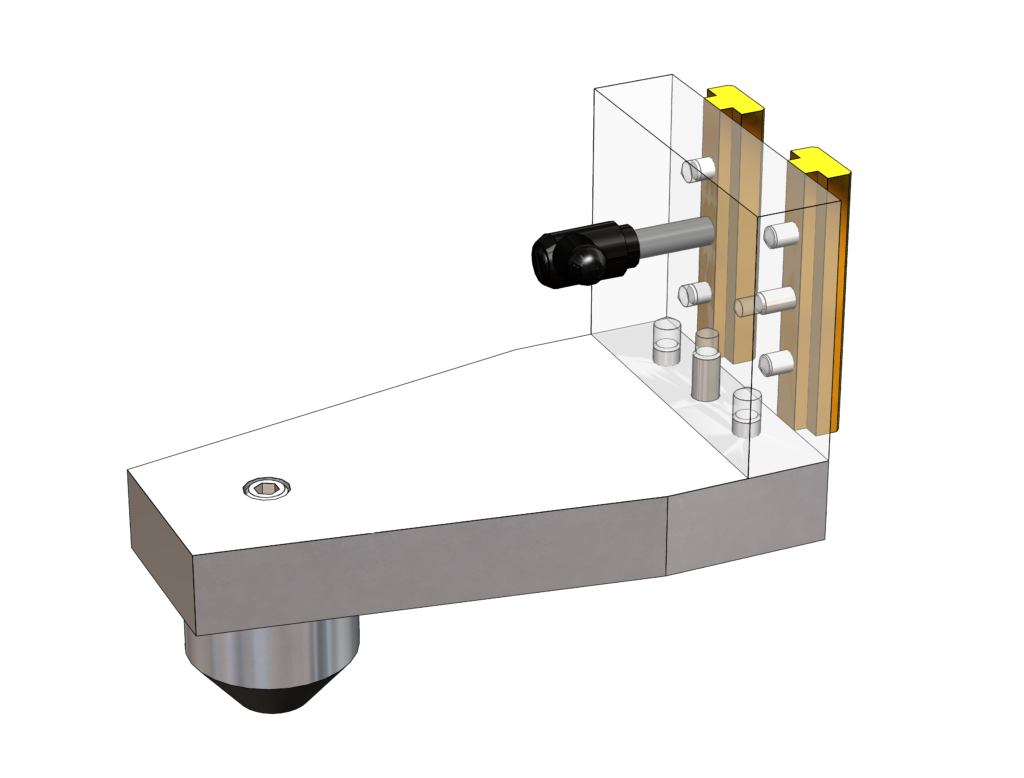

Precision Locating

In order to make our jig accurate, we had to implement techniques into the design to locate parts in precise locations. For example, we used dowel pins to line up parts whenever attaching parts with screws. We also spent a lot of time designing the sliding mechanisms to slide in only one axis (no wobble or play). All of this is to ensure our bike designs are fabricated with minimal defects, uncertainty, and guesswork.

Assembly/Fabrication

Our final manufactured design differed from the renders above as we opted to use as many off-the-shelf components as possible. This reduced complexity greatly and reduced the time needed in the machine shop which was limited due to COVID-19. All parts were machined by my partner and I.

Dummy Axle

In order to ensure proper alignment of the rear wheel of the bike, a dummy axle was created with a centering feature. The center indent on the dummy axle ensures it always sits in the centerline of the bike when placed in the jig. The outer surfaces of the dummy axle are spaced to match the hub of the bike.